Mezzanine floors - Timber or concrete, what is best for me?

A double-level office building is a great way to get more m² of office space without using any more land. It also creates a nice elevated workspace with a view.

A question we often get asked is what type of structure should the mezzanine be constructed out of? Should it be concrete, timber-framed, or CLT (cross-laminated timber)? What is cheaper, and what performs better?

The answer is, it depends on your situation and requirements. So we thought we’d take the time to explore the pros and cons of each construction type so you have the information to decide which is best for you.

Timber Framed mezzanine

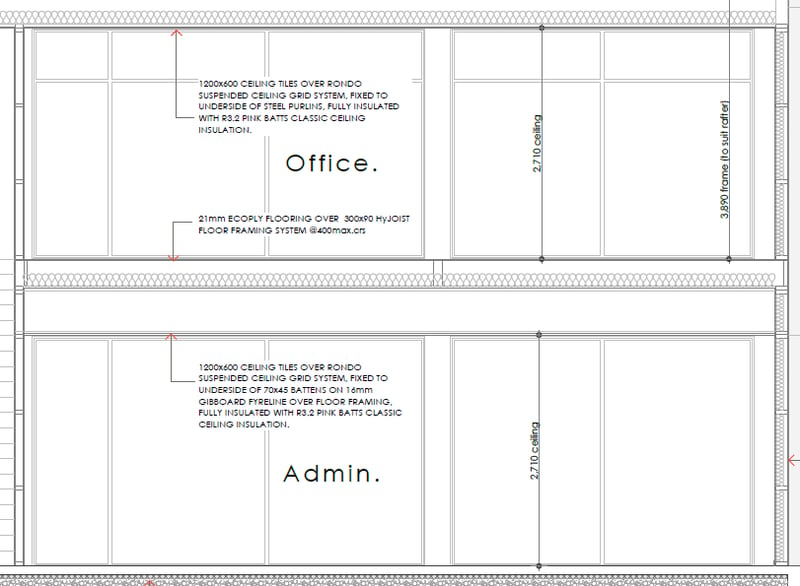

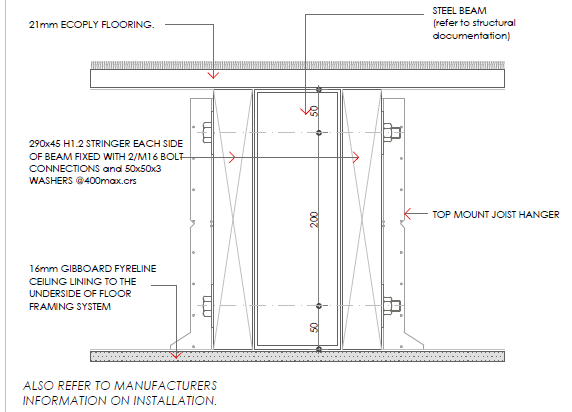

A timber-framed mezzanine is constructed of timber joists that either span between supporting beams or load-bearing walls. The joists are typically at around 400mm centres. The joists can be standard SG timber (which is a milled timber such as 190x45, 240x45, or 290x45) or a laminated joist such as LVL, glulam, or hyjoist.

Then insulation is placed between the joists and either plywood or strand board flooring (usually about 20mm thick) is laid over the joists.

If your floor requires a fire rating (which it very likely will) then the underside of the floor will need to be lined in fire-rated GIB. The ceiling can then be painted and left as is, but often in larger offices, a suspended ceiling will be installed to give space for services and air conditioning ducts, etc.

Any supporting walls will also need to be lined in fire GIB and any supporting steel would need to be fire rated with intumescent paint or lined in fire GIB. Below is a cross-section of a timber mezzanine floor:

What are the advantages of a timber-framed mezzanine?

This flooring system is used all over NZ in most houses and a lot of commercial buildings, so all builders are familiar with it. Onsite changes are typically quite straightforward as the whole floor system is constructed onsite.

For smaller mezzanines (under 150m²) it tends to be a good simple option that is cost-effective. It is especially cost-effective where the ground floor has walls that can be made load-bearing, i.e walls that are up to 6m apart.

What are the disadvantages of a timber-framed mezzanine?

The main disadvantages arise for larger floors (over 150-200m²). Noise transfer is typically a lot higher than concrete or CLT floors. This can be mitigated with insulation and larger joists but when there is a large upper level and a lot of people working in the building the noise transfer can become quite pronounced.

As the above images show, there are a lot of components to the floor - especially when a suspended ceiling is to be installed below. This means that on larger floors the labour component can quickly add up— which will make a cost much the same as a concrete floor.

Also, on larger floors a lot of steel or laminated beams/joists are required to avoid too many load-bearing walls; this also pushes the cost closer to concrete/CLT, and generally, they become a much more attractive option.

Concrete mezzanine

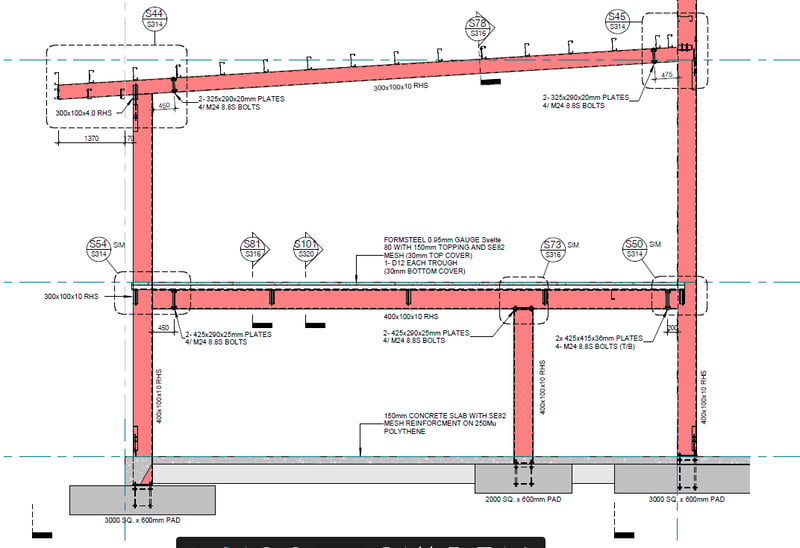

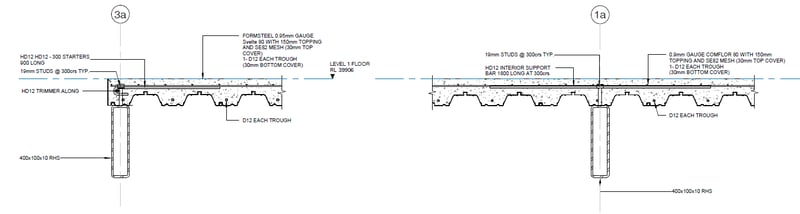

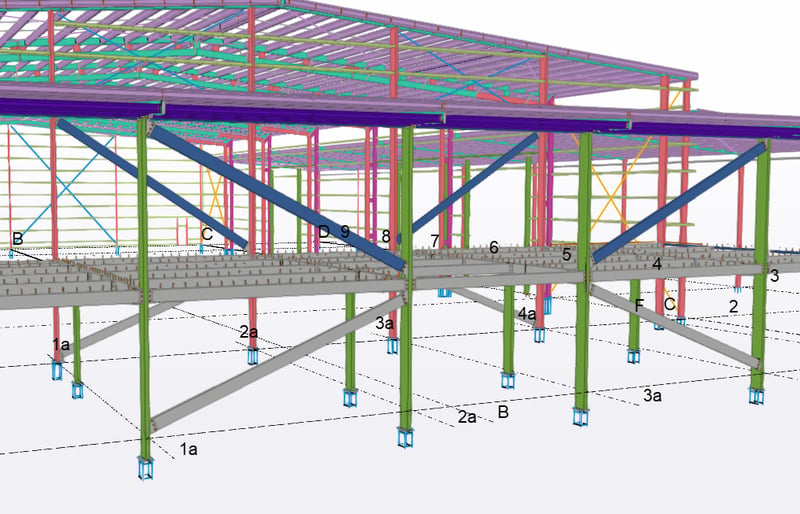

A concrete mezzanine is a concrete slab that is poured in situ and supported by steel beams and columns.

First of all, the steel beams and columns are installed to provide a steel structure that will support the concrete floor. Then a tray system such as ComFlor or HiBond is laid on top of the steelwork. Reinforcing is then laid on the floor, exterior boxing is placed, and then concrete is poured on top of the tray (or deck).

The concrete has a fire rating, so it is typically only the supporting steel that needs to be fire rated. This is usually done with intumescent paint, but it can be lined with fire GIB. Often the underside of the floor is left exposed and services are also exposed which creates a modern industrial look. Alternatively, a ceiling can be suspended to conceal services.

Below are some example details:

What are the advantages of a concrete mezzanine?

Short build time

For a large floor (over 300m²) a concrete system starts to become more cost comparable or even cheaper than a timber-framed option. While the steel and concrete in a concrete mezzanine floor do add to the cost, there are fewer labour hours required which can result in a shorter overall build time.

Acoustics

Typically a concrete floor has much better acoustic properties than a timber floor. For example, if you have a large upper level with a lot of people, a concrete floor will help reduce the noise transfer between levels.

Visual/Functional

Leaving the concrete and supporting steel exposed downstairs gives a clean industrial look that is very low maintenance. It is also a common system that commercial builders are well-versed in doing and it has been proven over many years. There is also onsite flexibility before the pour as the formwork and piping can be adjusted.

What are the disadvantages of a concrete mezzanine?

Weight

A concrete floor is heavy so this adds to the load on the ground. This is usually not an issue unless the ground is poor — in this case, the geotech investigations would advise on the best course of action.

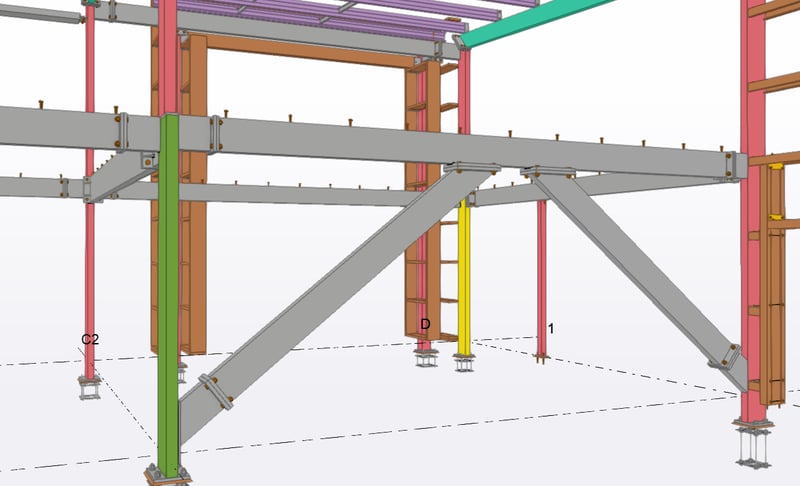

As the floor is heavy there are usually more bracing elements required in the office which is in the form of steel diagonals or ‘K’ frames (pictured below).

Angle Braces

These braces are not necessarily a large cost but they do tend to impact the windows. Either the space where there is bracing lined over and ‘hidden’ or the brace is just placed in front of the window as part of the look of the building.

CLT Panel Floor (Cross Laminated Timber)

A CLT Panel floor is very similar in principle to a concrete floor. However, instead of pouring a concrete floor on top of the steel structure, a 126mm thick timber panel is laid on top of the steel. The timber panel is made up by glueing together solid layers of timber to make a very thick and large panel.

For further explanation, please refer to this brochure.

Like a concrete slab, timber has a fire rating so it is typically only the supporting steel that needs to be fire rated. This is usually achieved with intumescent paint, but it can be lined with fire GIB. Often the underside of the floor is left exposed and services are also exposed. Alternatively, a ceiling can be suspended to conceal services.

What are the advantages of a CLT panel floor?

It is a faster option than a concrete floor as the timber only has to be laid onto the structure. Concrete requires the trays to be installed, reinforcing laid, and then the concrete placed and finished. Plus there is a cure time for the floor. This means that a CLT panel floor is likely cheaper than concrete and is certainly faster to install. In a recent construction, the builders allowed three days to install the CLT panel floor and had it completed in less than a day.

Concrete mezzanine floors can also require specialist contractors for the nelson studs and sometimes for pouring the floors. This may be a challenge if you are in a regional area. With a bit of training a builder should be able to easily install CLT as it is a timber product that uses typical fixing details.

It is also a lot lighter than concrete. This places less load on the footings, supporting steel, and bracing elements.

There are environmental advantages as well — Red Stag says that every m³ of timber stores 250 kg of carbon while producing every 1m³ of concrete emits 110kg of carbon.

It can also look really smart underneath if it is unlined and left as timber, but this is a matter of opinion.

What are the disadvantages of a CLT panel floor?

In the past, a reliable supply of CLT has been quite a problem, hence why XL Structural Steel and other commercial builders have not used it as much as other methods. It has typically been used in speciality projects that use a full timber system, or multi-level apartments - see an example of this here.

Typically a lot of CLT came from XLAM who is now Australian-based, but recently more manufacturing space has opened up in NZ which has given more options and capacity in the industry.

Structurally, the timber does not span as far between intermediate beams as concrete. This does not typically have too much of a cost impact.

The CLT requires additional protection (such as GIB) to get a fire rating above 60 minutes. This is not usually a problem as most floors typically only require a 60-minute rating.

The surface of the CLT is not as hard-wearing as concrete. This is not usually a problem for offices as the surface is covered in carpet/tiles anyway. However, if the CLT is to be exposed it does need coating systems to ensure its durability.

CLT can also be more difficult to adjust onsite as penetration notches and joints are done in the factory with CNC machines. This means it is treated a bit like pre-cast concrete with its own set of shop drawings.

Which type of mezzanine floor is best for me?

The first deciding factor is the type/size of your offices. If the offices are small and the upstairs is less than 150m² or 200m², then the most cost-effective option is a timber-framed floor. This is because it is likely that NZ3604 can be used to design the offices, avoiding extensive engineering and a lot of steel beams.

Also, if your downstairs area has a lot of rooms that are not going to change, a timber upper floor can be a great option as the lower level walls can be made load-bearing, saving on bespoke beam designs.

What if my offices are much larger?

If you are building a large office space (say 200-500m² per level), a concrete floor or CLT is likely the better option in terms of cost and long-term functionality.

At XL Structural Steel we have an in-house team of commercial and industrial building specialists

If you're still unsure or would like advice more specific to your situation, talk to our in-house team of commercial and industrial building specialists who can work alongside you to understand your building project needs and collaborate with you to define your design and budget requirements.

If you are interested in more about mezzanine floors and office design, read our article "What is the Best Way to Build an Office Block?"