Different portal designs for commercial buildings

By now, you probably know that industrial and commercial buildings can be constructed using numerous building systems, however, if you are considering getting your own purpose-built building you’re likely to want to know what building system is best for you.

This article is my effort to provide an objective explanation of the building systems along with their advantages and disadvantages so you can form your own opinion as to what is best for you.

There are two main building system categories for industrial building construction:

- Roll-formed steel buildings.

- Structural steel buildings.

What is roll-formed steel?

Image sourced from Shed Boss.

Image sourced from Shed Boss.

Roll-formed steel is where high tensile sheet metal is formed using consecutive sets of rolls to form an engineered shape (typically a C shape or Box shape).

Roll-formed steel is also called cold-rolled steel or lightweight steel and is typically 1-2mm thick and the profiled shape is what gives the member its strength.

What is structural steel?

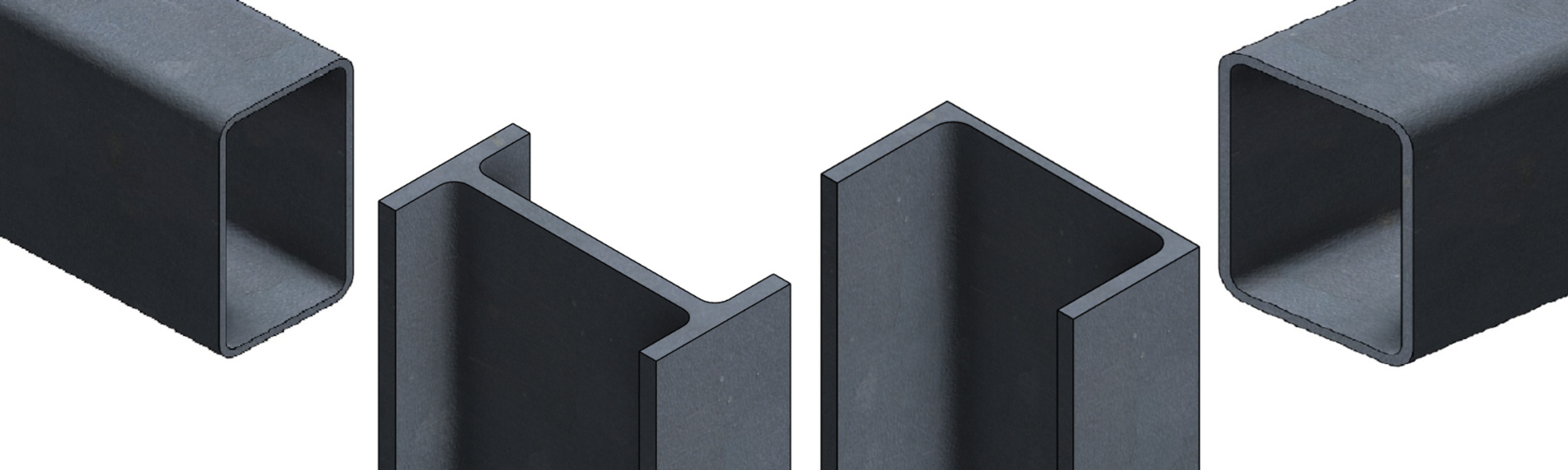

Image sourced from Steel & Tube.

Image sourced from Steel & Tube.

Structural steel is a generic name that covers a lot of steel you see all around you every day — in bridges, towers, and of course buildings. Some of the structural steel beam types you may have heard of before such as universal beams (UB), I beams, H beams, RSJ beams, square sections (SHS), round sections, and rectangular hollow sections (RHS).

Structural steel buildings are typically designed using universal beams (UB/I beams), lattice truss, rectangular hollow sections, or custom tapered members.

Roll-formed buildings vs structural steel buildings

Cold-rolled steel portal system advantages:

- Because of the lighter gauge steel, roll-formed buildings use less steel than structural steel buildings.

- By using less steel the buildings are generally cheaper.

- Being a lightweight design, the members and frames are also lighter to handle when constructing, which can save the need for heavy lifting equipment.

- Cold-rolled steel portal systems are prevalent amongst franchised shed/garage builders. There is likely to be a number of providers in all areas around NZ.

- Cold-formed building systems are typically a good fit for smaller spans and lighter commercial builds where durability is not a consideration.

- A lot of roll-formed buildings are designed with braces in the knee (or corners) and apex (top) to save cost on the portal frames as the members can be lighter due to the additional bracing these struts provide (although an upfront cost saving, they can limit the useability of the building).

Cold-rolled steel portal system disadvantages:

- As the cold-rolled portal frames get their structural strength from the profile/shape of the rolled member, any dent to the leg will create structural damage. This can easily be caused by a knock from machinery or forklift movement.

- If rust does form on the portals it quickly becomes structural damage due to the material being only 1-2mm thick.

- Often the design of a roll-formed shed has braces at the knee and apex which birds can perch and nest on.

- Knee and apex braces are not only a potential bird perch but can also protrude into the internal space of the building. Lowering the usable height of the building.

- Not typically suitable for integrating gantry cranes into the building design.

Structural steel advantages:

- Due to the wall thickness of structural steel, it will stand up to knocks from machines much better than lightweight, cold-rolled steel, giving long-term durability for industrial environments.

- Quick to install. Structural steel is bolted together which is quicker than fixing connections with lots of tek screws.

- Bolted connections — connections are bolted or welded during fabrication. This also gives a much stronger connection than using tek screws and pressed steel brackets.

- Structural steel is more suited for larger building spans and have greater design flexibility.

- They can be designed to take gantry cranes loads where required.

- Low lifetime cost of ownership. Structural steel typically requires little maintenance giving a low lifetime cost of ownership.

Structural steel disadvantages:

- Structural steel building design will require more steel than a roll-formed building meaning it would typically cost more than a roll-formed building.

- Due to the weight of the steel portals larger cranes/lifting equipment may be required in comparison to roll-formed buildings.

- May be considered over-engineered for small-span buildings where there is little risk of damage from vehicles or the building is to be an office/light retail space.

Why we use structural steel in our buildings

As the name suggests, XL Structural Steel provides a structural steel building system using Rectangular Hollow Section (RHS) profiles.

As the name suggests, XL Structural Steel provides a structural steel building system using Rectangular Hollow Section (RHS) profiles.

Over above other structural steel building designs, the XL building system also offers:

- Great aesthetics. The RHS profile gives a clean and compact look, giving a smart building design with an impressive visual appearance.

- Because of the size and wall thickness of the RHS, the portals perform exceptionally well under lateral loads. Looking for 30m clearspan and a design that can support 10-ton gantries? Not a problem!

- The XL portal system is typically optimised for clearspans between 20-40m.

- The XL system using RHS members has no need for large obtrusive apex or knee braces inside the shed. This gives maximum headroom and side room inside the shed, increasing the storage capacity for warehouses and reducing the chance of structural damage from moving machinery.

- The RHS enclosed portal system when combined with a boxed-in purlin, rested between portals, prevents birds from being able to perch.

In conclusion, when deciding on the right building design for your next project, there is a broad spectrum of designs along with varying attributes and qualities to consider.

If you are in the process of planning a new industrial or commercial building you may also be interested in our articles on the most efficient way to design an industrial building or the cost per m² of a commercial or industrial building. Alternatively please feel free to reach out to the team directly.